Thank you for your interest in Potain self-erecting tower cranes.

Please fill out the form below and a crane expert will contact in 1-3 business days.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies. To learn more view our cookie policy.

Downtown Squeeze No Problem for Compact Potain

A Potain Igo T 85 A self-erecting crane is speeding up production on a limited-space hotel site in rapidly expanding Austin, Texas.

Austin, Texas, is one of the fastest-growing cities in the United States, with its vibrant tech scene and inviting climate. As the population rises, so does the demand for housing, infrastructure, and retail properties. In addition to an influx of new residents, Austin — nicknamed “The Live Music Capital of the World” — is a thriving tourist destination, so the demand for hotel rooms has spiked, too.

Open spaces are at a premium, which often leads to creative ways of approaching new construction. For example, a 276-room hotel being built by general contractor Flintco LLC, just east of downtown, is surrounded by single-family residences, apartment complexes, and commercial and industrial properties, so the site is a very tight fit.

To put it bluntly, “We’re building a fairly large hotel on a postage stamp,” said Senior Superintendent H McMillan, who is overseeing the project for Flintco. “There is no room around the site for laydown. It’s difficult to just unload trucks delivering materials. Initially, the job had a top-slewing tower crane, but that proved to be ineffective. When I came on site, I was hopeful that we could come up with a solution that was more productive.”

Subcontractors Midwest Drywall Co. Inc. and McDonough Construction Rentals worked with McMillan and Flintco to find the solution. They determined that a Potain Igo T 85 A self-erecting tower crane with a footprint of roughly 15 ft by 15 ft, placed in what will be the hotel’s courtyard area, would be ideal. It has a variable height telescoping lattice mast of 66 ft to 75 ft, with the option to add three mast inserts for a horizontal jib hook height of up to 125 ft, to meet both capacity and reach requirements.

An easy choice

Midwest Drywall uses the Potain Igo T 85 A to pick 20-gauge decking bundles that weigh about 3,200 lbs and prefabricated cold-formed wall panels — some of which are up to 30 feet long and weigh roughly 2,500 lbs — and set them in place.

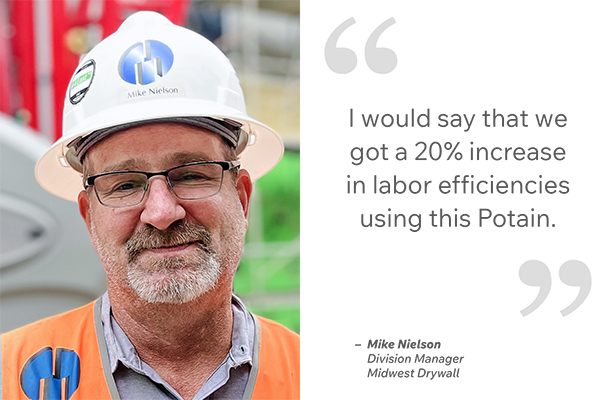

“It made the most sense to use the Igo because it sits in one spot and has the ability to easily reach all around the job site, from ground level to the upper floor,” said Midwest Drywall Division Manager Mike Nielson. “We considered using a forklift or bringing out a mobile crane on occasion, but once you get above the first floor, those weren’t good options. The Igo makes installation much more productive and efficient because without it we would have to move panels and decking by hand, which really isn’t feasible. We probably doubled the number of panels we can put up in a day, and our decking installs increased because we’re able to pick up full bunks, set them, and spread them out. I would say that we got a 20% increase in labor efficiencies using this Potain.”

McDonough Construction Rentals President Steve Ridout said that contractors nationwide are seeing similar results with the Potain Igo T 85 A, which has made it a popular choice for similar job sites since McDonough began representing the Potain self-erecting tower crane line about a year ago.

“It’s made for situations like this. The lifting capacity and reach are incredibly suitable for this type of tight, congested job site,” stated Ridout, who assisted Midwest and Flintco alongside McDonough National Sales Director Brian Morvant and Brian Lamont, a sales representative.

“Mike and Midwest gave us their loading and lifting characteristics, and we matched them up to the Igo T 85 A,” Ridout explained. “Our local Potain account rep was also a valuable resource in confirming this was the right machine and has given us and the contractors tremendous support along the way. We’re excited about having the line and the possibility of expanding it in the Texas marketplace.”

Increased communication and efficiency

The Igo T 85 A increased jobsite communication and efficiency because it is operated with a wireless radio remote. Operators are able to more easily see the load and can stay close to it as they are moving it into place.

“It’s the easiest controller you will ever use,” said Kassidy McCutcheon, who is a certified crane operator. “It has two joysticks — one for the cable and one for the swing. I can pick up the load and quickly and easily move it anywhere into place. It didn’t take long at all to get the hang of it. One nice feature of the controller is that it tells me the wind speed and how much the load weighs, so if there is an issue with either, I can make the call right away to not do the pick. It’s also very beneficial that I can walk around, follow the load and adjust as needed. On a wall panel, I can put it right in place and hold it there while it’s being secured down.”

Planning for future usage

According to McMillan, the Potain Igo T 85 A proved itself from the start.

“The setup was extremely easy,” said McMillan. “You drive it and unfold it. There is no need to pour a crane pad, which is expensive and time-consuming. It’s set up on timbers, and once we had the electrical hookup in place, it was right to work.”

McMillan added, “We were behind on the project until we got the Potain. It got the project back on track, and honestly, Midwest has gone so fast with the crane that we had some trouble keeping concrete ahead of them. That’s a good problem to have in the grand scheme of things.

It’s our first experience with this crane, and I’m told based on how it’s performed here that it’s already being looked at for future projects.”

Nielson said Midwest Drywall is also searching for jobs where the Igo T 85 A is the right fit.

“We will see the true return on investment at the end of the project, but just from our experience to this point, we know it’s positive when you factor in rental, teardown, set-up, and labor costs,” Nielson said. “Typically, subcontractors don’t operate cranes, but we have seen a real advantage with the Potain. It definitely breaks the misconception of whether a self-erecting crane makes sense for a company like ours.”

Left to right: Flintco Senior Superintendent H McMillan; Manitowoc Regional Business Manager David Polce; McDonough Construction Rentals team members Brian Lamont, Steve Ridout and Brian Morvant; and Midwest Drywall Division Manager Mike Nielson work together on a hotel project in Austin, Texas.